What to Consider Before Buying a Laser Engraver and Laser Cutter in 2023

Making the Right Choice for Your Creative and Business Needs

In the ever-evolving landscape of manufacturing and personal projects, laser engravers and cutters have become indispensable tools for creators and businesses alike. These versatile machines can transform a wide range of materials with precision and detail, making them an excellent addition to any workshop or business operation.

However, with the multitude of options available in the market in 2023, selecting the ideal laser engraver and cutter for your specific needs can be a daunting task. To ensure you make a well-informed choice, here are the key factors to consider before making your purchase.

1. Laser Power and Wattage

The power and wattage of the laser tube are pivotal factors that dictate the cutting and engraving capabilities of your machine. For light engraving on delicate materials, lower wattage (30-50W) lasers may suffice. In contrast, high-wattage lasers (80W and above) are essential for cutting through thicker and denser materials. It’s crucial to match the laser power to your intended applications.

2. Laser Type: CO2 vs. Fiber

There are two primary types of lasers in these machines: CO2 and fiber. CO2 lasers are versatile and well-suited for engraving and cutting non-metallic materials like wood, acrylic, and plastic. Fiber lasers, on the other hand, excel in metal engraving and cutting. Your choice depends on the materials you intend to work with.

3. Work Area Size

Consider the dimensions of the laser bed or work area. If you plan to work on larger projects, a machine with a larger work area is essential. Ensure that the size of the work area aligns with your project requirements, allowing you the flexibility to work on a variety of sizes and dimensions.

4. Speed and Precision

The speed at which the laser head moves and the precision it offers are critical for efficient and accurate results. Faster machines can increase productivity, while higher precision ensures intricate designs and fine details. Strike a balance between speed and precision that suits your needs.

5. Software and Compatibility

The software that operates your laser engraver and cutter plays a pivotal role in your user experience. Ensure that the machine is compatible with your preferred design software and offers user-friendly controls. A machine with intuitive software can save you time and frustration. We understand that investing in a laser engraver and cutter is a significant decision, and we want to make it even more appealing. With our exclusive Atomstack Coupon Code, you can enjoy a 30% discount on your purchase, making it an even more cost-effective choice.

6. Maintenance and Support

Like any piece of equipment, laser engravers and cutters require maintenance. Consider the availability of replacement parts, customer support, and the ease of maintenance when making your choice. A machine with readily available spare parts and a strong support system can reduce downtime and prolong the life of your equipment.

7. Ventilation and Safety

Laser machines produce fumes and emissions that can be harmful. Adequate ventilation is essential to ensure a safe working environment. Additionally, consider safety features such as emergency shut-off switches, interlock systems, and protective enclosures to protect both you and the machine.

8. Budget and Cost of Ownership

While investing in a laser engraver and cutter is a substantial commitment, it’s essential to consider not just the initial purchase cost but the total cost of ownership. This includes maintenance, replacement parts, and ongoing operating expenses like electricity and ventilation. Make a budget that encompasses all these factors to avoid surprises down the road.

9. Material Compatibility

Different laser machines are optimized for particular materials. Check whether the machine you’re considering is compatible with the materials you plan to work with. A machine that can handle a variety of materials offers greater versatility.

10. Brand Reputation and Reviews

Do thorough research on the brand and model you’re considering. Look for reviews and feedback from users in the laser engraving and cutting community. A reputable brand with positive reviews can provide peace of mind regarding the quality and reliability of your purchase.

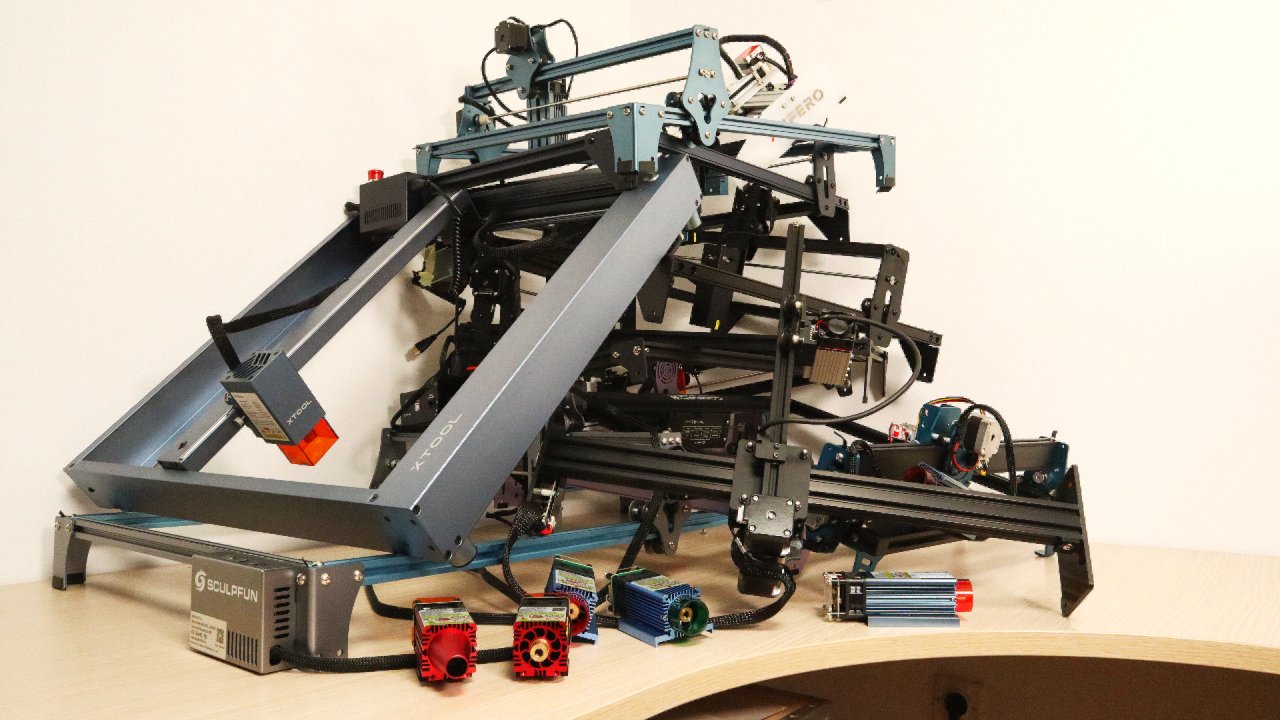

11. Future Expansion and Upgradability

Consider your long-term needs. Some machines offer upgradability options, allowing you to enhance their capabilities as your projects evolve. This can be a cost-effective way to adapt to changing requirements without needing to purchase an entirely new machine.

12. Training and Skill Level

Your familiarity with laser engraving and cutting technology matters. If you’re a beginner, choose a machine that offers user-friendly controls and training resources. Experienced users might opt for more advanced models with complex features.

13. Warranty and After-Sales Service

Check the warranty and after-sales service provided by the manufacturer or retailer. A solid warranty can offer protection in case of unforeseen issues. Ensure you understand the terms and conditions of the warranty thoroughly.

In Conclusion

Investing in a laser engraver and cutter in 2023 is an exciting step for your creative and business endeavors. To make the right choice, assess your specific needs and carefully evaluate the factors discussed above. Whether you’re a hobbyist, an entrepreneur, or a professional, a well-informed decision ensures that your laser machine becomes a valuable asset in realizing your creative vision.