Is This Is What You Need To Know About Electric Motors

An electric motor transforms electrical energy into mechanical energy through interaction between its magnetic field and current in its winding of wire, producing torque force on its shaft. surplus motor are the best Motors Remember Faraday’s famous experiment using a loop of wire and magnets; their combined force caused it to rotate continuously, leading to its eventual transformation into an electric motor. Electric motors represent an advanced form of this simple circuit.

Buy Electric Motors

Electric motors are electrical devices that convert electrical energy into usable mechanical energy through interaction between their magnetic field and current in its wire windings. Electric motors may use either direct current (DC), as found in batteries, or alternating current (AC), such as produced by power grids and generators.

Before purchasing an electric motor, it’s essential to carefully consider its application. Determine whether your motor will operate continuously or intermittently and for how long each time. In addition, having an estimate of how much torque and speed is required will also come in handy.

AC and DC motors are among the most frequently used electric motors, and can be distinguished from one another by requiring different forms of electricity for powering them respectively. An AC motor requires an alternating current power source while DC is powered directly, with AC having a starting mechanism such as capacitor or start winding while DC does not. Construction options available to users range from industrial steel band designs with open designs or enclosed cast iron casings with shockproof coatings to protect internal components in harsh environments like manufacturing plants and mines.

Used Electric Motors

Electric motors convert electrical energy to mechanical energy through rotational movement. Although their operation differs from that of an electric generator, electric motors still employ similar electromagnetism principles to spin coils of wire in magnetic fields to perform useful work. Motors are commonly found in home and commercial equipment like fans, power tools, electric vehicles and even hybrid cars.

Electric Motors can be divided into different categories depending on their power source, application, and construction. DC motors may be powered by rectifiers, batteries or power supplies while AC motors use either AC generated from grid power generators and inverters or by inverters to produce direct current (DC). They may also be classified by motion output type – brushless single phase three phase liquid- or air-cooled; motion output type could include motion induced or direct current output and type of motion output such as single or three phase liquid cooled motors are other characteristics to consider before classifying an electric motor into its respective category.

An electric motor contains both the rotor and stator within its housing, as well as a fan that draws ambient air in order to cool the coils and dissipate heat produced by its rotating shaft. When considering operating voltage levels for any particular motor, excessive or inadequate voltage could damage equipment and pose fire risks; its rated operating voltage must also be taken into consideration; too high or too low voltage levels could damage equipment and create fire hazards; both parts must also be kept clean to maximize performance and lifespan, with additional lubrication being added based on environment or use; results of routine inspections must also be documented.

Surplus Motors

Electric motors are used to convert electrical energy into mechanical energy. When you turn on your mixer in the kitchen, for instance, an electric motor powers rotating blades which mix and mash ingredients together. They’re also widely employed in industrial settings such as machine tools, blowers, turbines and pumps as well as motor vehicles and household appliances. Motors may even serve as generators to convert mechanical into electrical energy! buy electric motor from surplusrecord industrial electrical motors are the best buy of electric motor used electric motor for sale at surplusrecord. surplus motor are the best MotorsAn electric motor operates through electromagnetism and comprises two mechanical parts – the stator is fixed while its rotating counterpart, known as a rotor, is mobile – as well as two electrical ones: field magnets and an armature coil which encircle its rotor. Fleming’s left-hand rule guides their interaction.

Differing electric motors use different power sources, with each differing in terms of construction, type of movement output, speed and size. Some have single or three-phase ratings with either brushless or brushed motion and either AC or DC motors depending on which source is driving them; DC motors can be powered via rectifiers and batteries while AC motors utilize AC sources like the electricity grid and electrical generators as their energy source.

Industrial Electric Motors

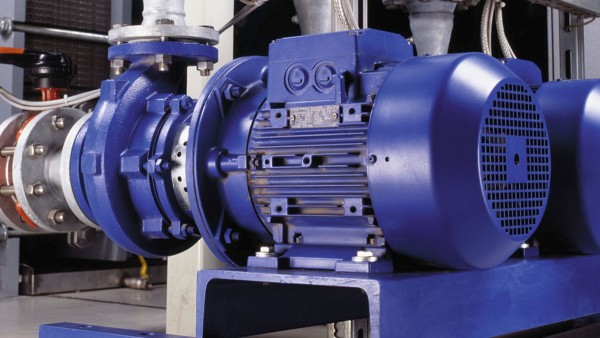

Industrial applications utilize electric motors to convert electrical power into mechanical motion that drives conveyor systems, pumps, hoists and machine tools. Electric motors may run on either DC current from sources like the grid or generators or AC current from generators; they may be either brushed, brushless, three-phase or two-phase configurations; gearboxes may also be added in order to increase torque as needed.

Maintenance is key in optimizing electric motor lifespans and performance. A regular cleaning schedule helps remove dust and grease build-up that reduces efficiency and accelerates wear-and-tear, as well as providing necessary lubrication levels – too little lubrication may lead to friction problems while too much may lead to premature wear – while using what the manufacturer recommends can increase both longevity and performance levels of an electric motor.

No matter whether working in a commercial or industrial environment, selecting an electric motor of appropriate size for any given task can be essential to its success. Sizing depends on required speed, power and torque specifications as well as factors like operating conditions and duty cycle – oversizing can lead to premature wear-and-tear and decreased efficiency, while under-sizing may create costly repairs later down the line.

Another consideration in selecting an electric motor is its energy efficiency, which can impact operational costs and environmental impacts. A motor with an IE5 rating consumes less than half the electricity as non-efficient models; International Efficiency (IE) standards define how energy efficient low-voltage AC motors are by listing losses; there are five levels of energy efficiency listed from IE1 through IE5, with the latter representing optimal energy performance.