Exploring the Excellence: Choosing the Right Nitinol Wire Supplier

Overview:

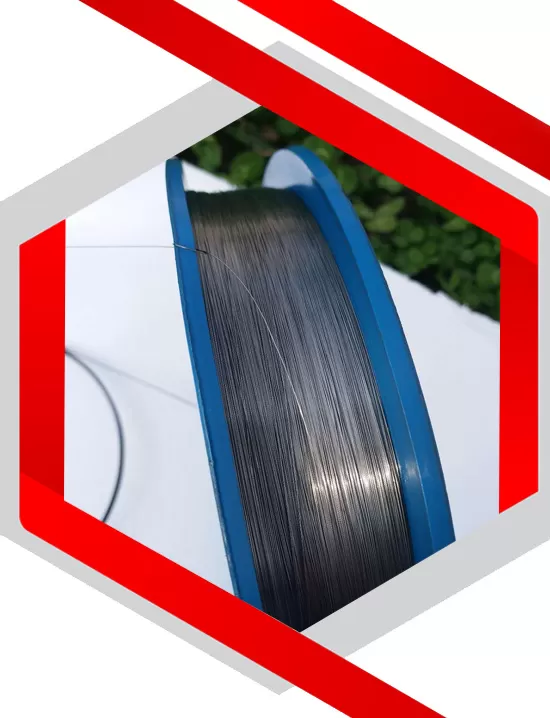

Shape memory and superelasticity are well-known characteristics of nitinol wire, an exclusive alloy of nickel and titanium that is indispensable to many industries. To guarantee that your projects receive the best quality and dependability possible, we set out on a journey in this blog to walk you through the process of choosing the ideal Nitinol wire provider.

An Overview of the Special Properties of Nitinol

Explore the unique qualities of Nitinol wire, such as its remarkable flexibility and capacity to “remember” its original shape. Knowing these characteristics paves the way for choosing a provider who can provide Nitinol wire that satisfies the particular needs of your project.

Applications in Industry: Where Nitinol Wires Are Brilliant

Nitinol wires are used in many different industries, including robotics, aircraft, and medical equipment. Examine how nitinol is used in different sectors and how the quality of the nitinol wire you receive might be affected by a supplier’s experience serving these applications.

Quality Assurance and Certifications: Non-Negotiable Standards

Ensuring Nitinol quality is of utmost importance. Seek out vendors of Nitinol wire that have the necessary certifications to make sure the alloy satisfies industry requirements. A quality-focused supplier ensures that your Nitinol wire will function dependably in your applications.

Customization: Fitting Nitinol Wire to Your Requirements

Every project has different needs. Look for manufacturers of Nitinol wire that have alternatives for customization, like different surface treatments, lengths, and diameters. Customization guarantees that the Nitinol wire will precisely match your project’s requirements.

Worldwide Coverage and Delivery Schedules: Guaranteeing Prompt Access

The reach of your Nitinol wire supplier is important in a global market. Look at vendors who have a wide customer base and dependable delivery schedules. If you want to avoid delays in the completion of your project, you must have timely access to Nitinol wire.

Customer Testimonials: Practical Advice

Consumer reviews offer important information about the dependability and caliber of services offered by Nitinol wire suppliers. Examine customer endorsements and reviews to learn more about the supplier’s performance history and capacity to satisfy demands from clients.

Competitive Pricing: Judging between Price and Quality

Cost is an important factor, but Nitinol wire quality shouldn’t be sacrificed for it. Look for vendors who can provide affordable prices without compromising the quality of the product. A healthy mix of price and quality ensures that your investment is both reasonable and reliable.

In conclusion, selecting the best Nitinol wire supplier is essential to the accomplishment of your projects. You may choose a supplier with confidence that meets the specific requirements of your project by being aware of the qualities of Nitinol, investigating its applications in the industry, and taking into account elements like certifications, customization, and customer reviews. Enhance your projects by using Nitinol wire, which can be obtained from a reliable supplier that is committed to quality.

For more information, please visit our site: https://www.smalloys.com/nitinol-wire-stockist-supplier/