Does Galvanization just Apply to Steel in Pakistan?

Galvanization, in the world of manufacturing and construction galvanization is a word which is often mentioned. When discussing ways to protect metal surfaces from rust. Although galvanization is an extremely popular method of protecting steel from corrosion and rust. But its application and scope are not limited to the boundaries of Pakistan. The article below we’ll look into this world of galvanization by investigating. Its fundamentals, methods and their significance not just in Pakistan but as well on a global level.

What is Galvanization?

The fundamental principle behind Galvanization is that it is the procedure of applying a zinc coating on iron or steel objects to keep corrosion. The coating functions as a sacrificial shield and corrodes in the place of the metal beneath. It’s a type of corrosion protection that extends the life of steel components and structures.

The Galvanization Process:

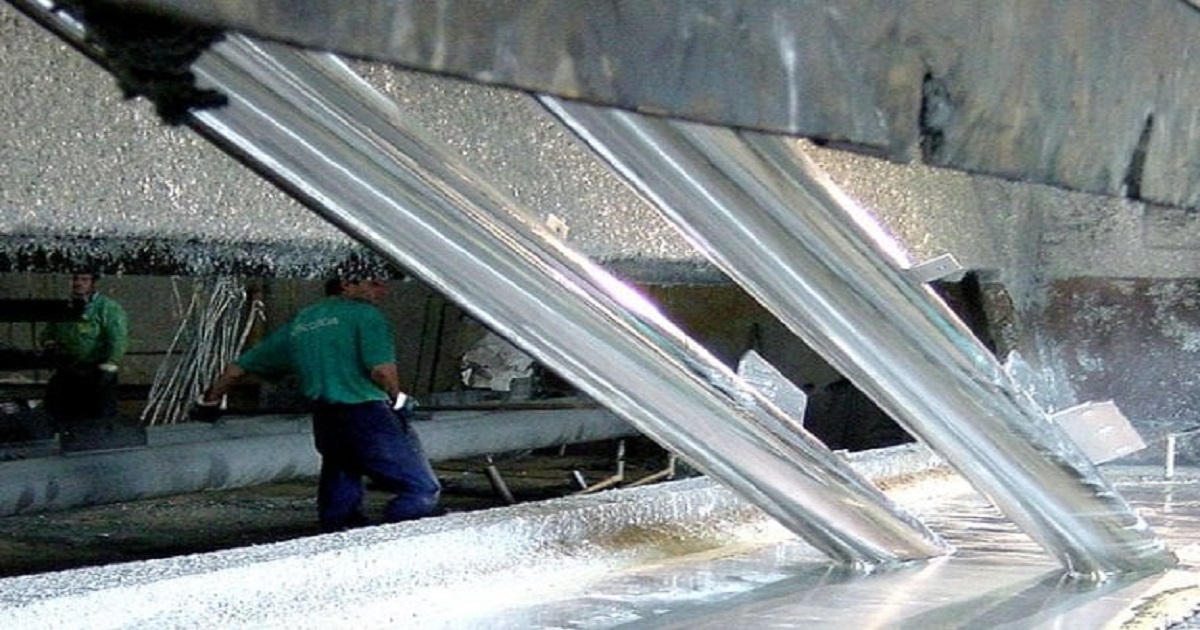

The process of galvanization typically involves cleaning the steel’s surface. And then soaking it in an encasement of molten zinc in high temperatures. This causes an appearance of bound zinc layer on the steel, forming the appearance of a shield. That protects it from the elements like oxygen and moisture.

Why do we need to galvanize Steel?

Galvanization is a vital stage in the production of steel industry for a number of reasons. It increases the strength of steel and makes it more suitable for outdoor usage, and lowers maintenance costs. In addition, galvanized steel is widely used. In many different areas, from construction to automobile manufacturing.

Galvanization Beyond Pakistan:

Global Use of Galvanized Steel:

While galvanization is crucial to the production of steel in Pakistan but its importance extends all over the world. Numerous countries depend on galvanized steel in construction projects, infrastructure building. As well as the manufacture of everyday products. Its resistance to corrosion makes it a preferred choice for areas that have high humidity or close proximity to saltwater.

Automotive Industry:

In the automotive industry worldwide galvanized steel is widely utilized. To make automobile bodies and other components. The resistance to corrosion of galvanized steel. Assures the long-term durability and safety of automobiles, regardless of their location.

Construction and Infrastructure:

All over the world galvanized steel is crucial roles for bridges and structures. As well as various infrastructure projects. Its strength and durability makes it a popular material, particularly in regions that are prone severe weather.

Galvanization Challenges:

Environmental Concerns:

Although galvanization has many advantages however, it’s not without difficulties. The impact on the environment of galvanizing. Particularly in relation to emissions and waste disposal have raised concern in recent time. There are efforts underway to design greener galvanizing methods.

Conclusion:

In the end Galvanization isn’t limited to Pakistan it is a worldwide practice that has a broad range of uses. It is a key element within the field of steel production, increasing the life span of steel products. And contributing to many industries worldwide.

FAQs:

Galvanization is only used to treat steel?

While galvanization is typically used to protect steel, it could also apply to different metals such as iron to avoid corrosion.

How long will the galvanized steel keep its shape?

The lifetime of galvanized steel is variable according to the environmental conditions. However it can last for a long time in the majority of cases.

Are there green galvanization techniques?

Yes, there is research ongoing to improve environmentally-friendly galvanization methods. That reduce the amount of waste and emissions.

Is galvanized steel able to reused?

Galvanized steel can be recyclable. Which makes it a green option for a variety of applications.

What are the differences between hot-dip galvanization and electro-galvanization?

Hot-dip galvanization involves immersing steel in molten zinc. While electro-galvanization uses an electrical current to deposit zinc onto the steel surface. The hot-dip galvanization process tends to produce more durable and thicker coatings.