Bonded Magnets Market Size, Share, Analysis and Forecast (2022-2030)

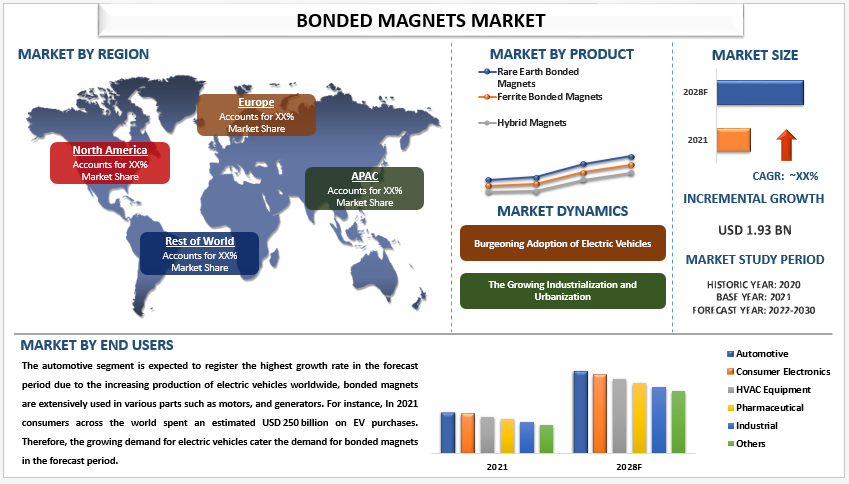

In an increasingly technology-driven world, magnets play an essential role in various industries, from automotive to electronics. Among the various types of magnets available, bonded magnets have gained significant attention due to their versatility and unique properties. This article delves into the Bonded Magnets Market, exploring its growth, applications, manufacturing process, and future prospects. According To UnivDatos Market Insights – The bonded magnets market was valued at USD 1.93 Billion in 2021 and is expected to grow at a strong CAGR of around 6.94% during the forecast period (2022-2030) owing to the burgeoning adoption of electric vehicles globally.

Access sample report (including graphs, charts, and figures):https://univdatos.com/report/bonded-magnets-market/get-a-free-sample-form.php?product_id=40370

Introduction

Magnets have been an integral part of our lives for centuries, but in recent times, their importance has grown exponentially, thanks to technological advancements. Bonded magnets, in particular, have emerged as a remarkable solution in various industries, owing to their unique properties and applications. In this article, we will explore the Bonded Magnets Market, shedding light on its growth trajectory, manufacturing process, applications, and what the future holds.

Understanding Bonded Magnets

2.1. What are Bonded Magnets?

Bonded magnets are a type of permanent magnet that is composed of magnetic powders (usually ferrite or rare-earth materials) mixed with a binder (typically a polymer resin). This mixture is then compressed and formed into the desired shape. The result is a highly customizable magnet that can be tailored to suit specific applications.

2.2. Types of Bonded Magnets

Bonded magnets come in various types, each with its unique characteristics. The most common types include:

- Isotropic Bonded Magnets: These magnets have uniform magnetic properties in all directions and are ideal for applications where the magnetic field needs to be equally strong in all axes.

- Anisotropic Bonded Magnets: Unlike isotropic magnets, anisotropic bonded magnets have a preferred direction of magnetization, making them suitable for applications where a specific orientation of the magnetic field is required.

Manufacturing Process

3.1. Binder Materials

The choice of binder material is critical in the manufacturing of bonded magnets. It not only holds the magnetic particles together but also affects the magnet’s performance. Common binder materials include epoxy, nylon, and polyphenylene sulfide (PPS).

3.2. Mixing and Compounding

The process begins by mixing the magnetic powders and binder material. The proportions are carefully controlled to achieve the desired magnetic properties. After mixing, the compound is compounded to create a homogenous mixture.

3.3. Forming and Curing

Once the mixture is ready, it is formed into the desired shape. This can be done through injection molding, compression molding, or extrusion. The formed magnets are then cured, which involves subjecting them to heat to harden the binder material and set the magnetic properties.

Applications

Bonded magnets find applications in various industries due to their versatility and customizable nature. Some key sectors where bonded magnets are extensively used include:

4.1. Automotive Industry

In the automotive industry, bonded magnets are used in various components, including electric motors, sensors, and actuators. Their lightweight and efficient magnetic properties contribute to the development of electric and hybrid vehicles.

4.2. Electronics and Appliances

Bonded magnets play a crucial role in consumer electronics and appliances. They are used in speakers, headphones, and hard disk drives, ensuring precise and reliable performance.

4.3. Medical Devices

The medical field benefits from bonded magnets in applications such as magnetic resonance imaging (MRI) machines, where strong and stable magnets are essential for diagnostic accuracy.

Advantages of Bonded Magnets

Bonded magnets offer several advantages over other types of magnets:

- Customizability: Bonded magnets can be tailored to meet specific application requirements.

- Cost-Effectiveness: The manufacturing process is relatively cost-effective, making them a viable choice for various industries.

- High Precision: They offer precise control over magnetic properties.

- Environmental Friendliness: Bonded magnets are eco-friendly and can be recycled.

Challenges in the Bonded Magnets Market

While bonded magnets offer numerous benefits, they are not without challenges. One of the main challenges is their susceptibility to demagnetization at elevated temperatures. This limitation necessitates careful consideration of operating conditions in certain applications.

Market Trends

The Bonded Magnets Market is subject to several noteworthy trends:

- Miniaturization and Electronics: The trend toward smaller electronic devices continues to drive the demand for miniaturized, high-performance magnets.

- Renewable Energy: The push for clean energy sources has led to increased use of bonded magnets in wind turbines and electric vehicle components.

- Aerospace Industry: Bonded magnets are finding applications in aerospace, particularly in control systems and sensors.

Future Prospects

The future of bonded magnets looks promising, with several exciting prospects on the horizon:

8.1. Miniaturization and Electronics

As electronic devices become smaller and more powerful, the demand for miniaturized, high-performance magnets will continue to rise. Bonded magnets are well-positioned to meet this demand, thanks to their customizability and precision.

8.2. Renewable Energy

The global shift toward renewable energy sources, such as wind and solar power, will drive the demand for efficient and reliable magnets. Bonded magnets are expected to play a significant role in the development of clean energy technologies.

8.3. Aerospace Industry

In the aerospace industry, where lightweight and high-performance materials are paramount, bonded magnets are likely to find increased usage in control systems, sensors, and other critical applications.

Environmental Considerations

In an era of growing environmental awareness, it’s essential to note that bonded magnets are relatively eco-friendly. They can be recycled, reducing their environmental impact compared to some other types of magnets.

Conclusion

The Bonded Magnets Market is poised for growth, driven by the increasing demand for miniaturized, precise, and environmentally friendly magnetic solutions. As industries like automotive, electronics, and renewable energy continue