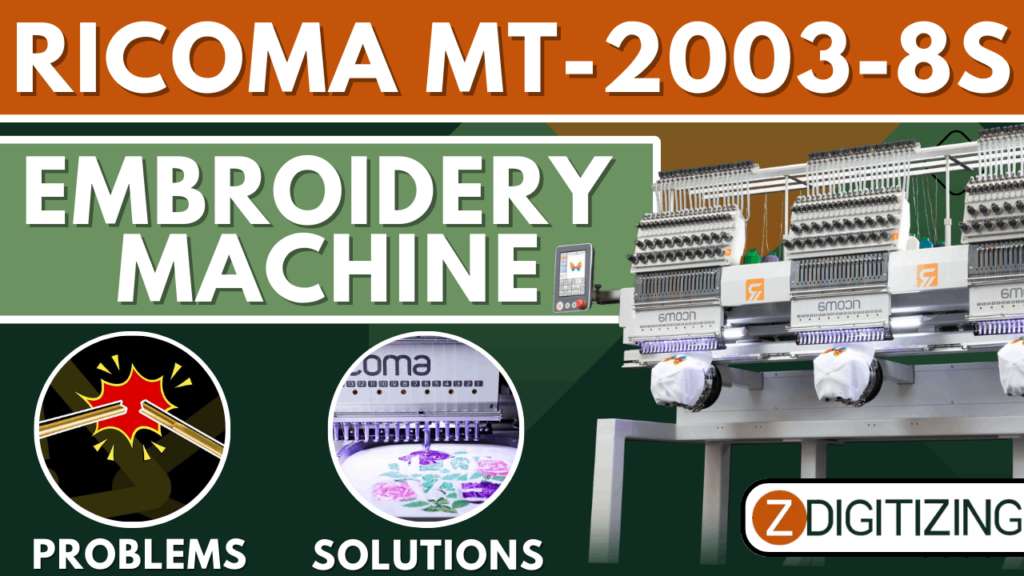

Biggest causes of Ricoma MT-2003-8S problems and how to prevent them

The Ricoma MT-2003-8S is a high-quality, multi-needle embroidery machine known for its precision and efficiency. While it’s a powerful tool for creating beautiful embroidery designs, even the best machines can encounter issues over time. In this comprehensive guide, we’ll explore the most significant causes of problems with the Ricoma MT-2003-8S and provide preventative measures to ensure smooth operation. Additionally, we’ll delve into the roles of embroidery digitizing companies, machine embroidery designs, vector art services, and ZDigitizing in optimizing and maintaining this embroidery workhorse.

Introduction to the Ricoma MT-2003-8S

The Ricoma MT-2003-8S is a multi-needle embroidery machine designed for both hobbyists and professionals. It boasts a user-friendly interface and an impressive array of features that make it ideal for intricate machine embroidery designs.

Understanding the Importance of Preventative Maintenance

Before we explore common problems and their solutions, let’s highlight the importance of preventative maintenance. Regular care and maintenance not only extend the lifespan of your Ricoma MT-2003-8S but also ensure consistent performance. By addressing potential issues before they escalate, you can prevent costly downtimes and maintain the quality of your embroidery.

Common Problems and Prevention

1. Thread Breakage

Problem: Frequent thread breakage can disrupt your embroidery project and leave it incomplete.

Prevention:

- Use high-quality embroidery thread that is suitable for your machine.

- Ensure proper threading by following the manufacturer’s guidelines.

- Adjust the thread tension to match the fabric and design specifications.

2. Bird’s Nest Underneath the Fabric

Problem: A tangled mess of thread underneath the fabric can lead to incomplete or messy embroidery.

Prevention:

- Properly wind and insert the bobbin.

- Re-thread the upper thread with care.

- Check the needle for any damage and replace it when needed.

3. Misalignment of Embroidery Designs

Problem: If your embroidery designs are misaligned, it can result in an unsightly finished product.

Prevention:

- Hoop the fabric carefully to ensure proper alignment.

- Use the correct stabilizer for the fabric.

- Calibrate the machine to adjust the design placement if necessary.

4. Thread Looping or Skipped Stitches

Problem: Thread looping or skipped stitches can result in subpar embroidery quality.

Prevention:

- Choose the right needle for the fabric type and adjust the needle size accordingly.

- Check the needle for any damage and replace it as needed.

- Ensure proper fabric stabilization to prevent fabric movement.

5. Design Not Recognized by the Machine

Problem: Sometimes, the Ricoma MT-2003-8S may not recognize or read the design file.

Prevention:

- Verify that the design file format is compatible with the machine.

- Ensure that the design file is free from errors or corruption.

- Re-upload or reformat the design if necessary.

Optimizing Your Ricoma MT-2003-8S Embroidery Machine

Beyond addressing common problems, there are ways to optimize your Ricoma MT-2003-8S for exceptional embroidery results.

1. Regular Cleaning and Lubrication

Dust and lint can accumulate inside the machine, leading to potential issues. Regular cleaning and lubrication, following the manufacturer’s instructions, are essential for keeping your machine in top working condition.

2. Use High-Quality Embroidery Thread

Invest in high-quality embroidery thread from a reputable source. Quality thread reduces the risk of breakage and enhances the overall quality of your embroidery designs.

3. Leveraging Embroidery Digitizing Companies

Embroidery digitizing is the process of converting images or designs into digital files that your machine can read. Embroidery digitizing companies specialize in this process and can help you optimize your designs for the Ricoma MT-2003-8S.

When selecting an embroidery digitizing company, look for expertise in creating files that are compatible with your machine’s requirements. They can adjust factors like stitch density and direction to ensure your designs look flawless.

4. Machine Embroidery Designs and Vector Art Services

Machine embroidery designs are at the core of your project. These designs, typically available in digital formats, contain the instructions for your embroidery machine to create the pattern. You can find a vast array of machine embroidery designs, from intricate florals to whimsical characters and elegant monograms.

When selecting machine embroidery designs for your Ricoma MT-2003-8S, consider factors like size, density, and theme. Ensure that the design fits the size of your project and that it’s not overly dense for the fabric you’re using. The theme should complement your project’s style.

Vector art services offer clean, scalable designs that maintain their quality regardless of size. This can be invaluable when you need custom logos or intricate patterns for your embroidery.

5. ZDigitizing for Complex Designs

ZDigitizing specializes in refining and optimizing embroidery designs, making them suitable for machine embroidery. This service is particularly valuable for intricate or complex designs that require precise adjustments to ensure high-quality results.

Conclusion: Mastering the Ricoma MT-2003-8S

In conclusion, the Ricoma MT-2003-8S is a versatile and reliable embroidery machine capable of producing stunning embroidery designs. While it may encounter common issues, these can be easily resolved with proper maintenance and attention to detail. By investing in high-quality materials, exploring embroidery digitizing company, and utilizing machine embroidery designs and vector art services, you can unlock the full potential of your machine and take your embroidery to the next level.