Air Shower in Qatar: Navigating Clean Environments

Air showers, a critical component of controlled environments, have evolved significantly over the years. From their humble beginnings to sophisticated modern designs, these chambers play a pivotal role in maintaining cleanliness in various industries. This article explores the unique context of air showers in Qatar, their design and operation, benefits, challenges, and future trends.

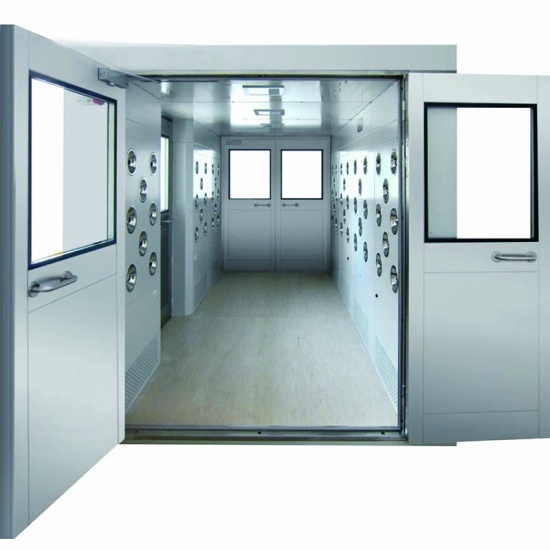

Definition of an Air Shower

An air shower is a self-contained chamber that individuals must pass through before entering a cleanroom or controlled environment. It serves as a decontamination gateway, removing particles from personnel and objects, and preventing contamination in critical areas.

Significance in Controlled Environments

In industries such as pharmaceuticals, semiconductor manufacturing, and biotechnology, maintaining a sterile environment is paramount. Air showers act as the first line of defense, ensuring that only properly decontaminated individuals and objects enter these sensitive spaces.

Evolution of Air Showers

1. Historical Perspective

The concept of air showers dates back to the mid-20th century when cleanroom technology emerged. Early air showers were rudimentary, but their importance in preventing contamination was evident.

2. Technological Advancements

Advancements in engineering and technology have led to the development of highly efficient air shower systems. Modern designs incorporate HEPA and ULPA filters, advanced airflow patterns, and sophisticated control systems.

Importance in Qatar

1. Unique Environmental Challenges

Qatar, with its arid climate and frequent sandstorms, presents unique challenges for maintaining clean environments. Air showers play a crucial role in mitigating the impact of external contaminants.

2. Industrial Applications

From the oil and gas sector to the healthcare industry, Qatar’s diverse economy relies on stringent cleanliness standards. Air showers find applications in various industries to meet these standards.

Design and Construction

1. Structural Components

Air showers typically consist of a chamber with doors on either end, a control panel, and a sophisticated air filtration system. The materials used in construction must be durable and easily cleanable.

2. Airflow Systems

The effectiveness of an air shower in Qatar depends on the design of its airflow systems. Properly engineered systems ensure uniform distribution of clean air, removing particles from head to toe.

Maintenance and Operation

1. Regular Checks and Inspections

Routine maintenance and inspections are critical to ensuring the continuous functionality of air showers. Filters need regular replacement, and sensors must be calibrated to maintain optimal performance.

2. Training for Proper Usage

Proper training for personnel is essential. Users must understand the correct procedure for passing through an air shower to maximize its effectiveness in contamination control.

Benefits of Air Showers

1. Contamination Control

The primary benefit of air showers is their ability to control contamination, preventing the introduction of particles into critical environments.

2. Employee Health and Safety

By ensuring that employees enter clean areas, air showers contribute to maintaining a healthy and safe working environment, reducing the risk of exposure to harmful substances.

Challenges in Implementation

1. Cost Considerations

The initial investment in air shower systems can be substantial, posing a challenge for some industries. However, the long-term benefits often outweigh the upfront costs.

2. Adaptation in Different Industries

Implementing air showers may require adjustments based on the specific needs of different industries. Customization is key to successful integration.

Case Studies

1. Successful Applications in Qatar

Several industries in Qatar have successfully implemented air showers, showcasing their effectiveness in real-world scenarios.

2. Lessons Learned

Examining case studies provides valuable insights into best practices and potential pitfalls, informing future implementations.

Future Trends

1. Technological Innovations

Continued advancements in sensor technology, automation, and materials will drive innovations in air shower design, enhancing their efficiency and reliability.

2. Potential Advancements in the Region

As Qatar continues to invest in various industries, the demand for cutting-edge cleanroom technologies, including air showers, is expected to grow.

Comparison with Other Cleanroom Technologies

1. Pros and Cons

Comparing air showers with alternative cleanroom technologies helps industries make informed decisions based on their specific requirements.

2. Suitability in Different Scenarios

Understanding the strengths and limitations of air showers enables industries to choose the most suitable contamination control method for their unique needs.

Regulations and Compliance

1. Local Standards in Qatar

Adherence to local cleanliness standards is crucial for industries operating in Qatar. Understanding and complying with these standards is imperative for regulatory approval.

2. International Guidelines

Many industries in Qatar operate on a global scale. Complying with international guidelines ensures alignment with best practices and facilitates international collaboration.

Environmental Impact

1. Energy Efficiency

Efforts to enhance the energy efficiency of air showers contribute to sustainable practices, aligning with Qatar’s commitment to environmental responsibility.

2. Sustainable Practices

Exploring ways to reduce the environmental impact of air shower systems promotes sustainability and aligns with global efforts to minimize carbon footprints.

Conclusion

In conclusion, air showers play a vital role in maintaining clean environments, especially in regions with unique challenges like Qatar. As technology advances, these systems will continue to evolve, contributing to safer and more efficient industries.

FAQs

Q. Are air showers only used in cleanrooms?

Ans. Air showers are primarily used in cleanrooms but have applications in various industries requiring contamination control.

Q. How often should air shower filters be replaced?

Ans. Filter replacement frequency depends on usage but generally ranges from three to six months.

Q. Can air showers handle different types of contaminants?

Ans. Air showers are effective against particulate contaminants but may not be suitable for handling chemical or biological contaminants.